Burj Dubai Lake.

An area of 20,000 square meters of the lake was previously used as a temporary lake to capture storm water runoff and had been subjected to bacterial growth. These areas were cleaned to remove bacterial growth and then treated with X-Treat Sanitizer to sanitize the surface of the concrete to prevent future bacterial growth. Surface preparation was completed using a captive blasting technique. Six captive blast teams were able to prepare 6000m2 of concrete surface per day. This process produced a lightly exposed aggregate finish that revealed all the bug holes (blow holes). X-Shield Bug Fill which is a two component high-build thixotropic epoxy resin. It was used to fill bug-holes and surface imperfections prior to coating the lake bed.

Hollywood FL USA, October, 2007

Only 4 years old and a central feature of the prestigious Westin Diplomat Hotel, the group of 3 fountains was discovered to be leaking water into the foyer and below ground parking area. The fountain constructed from concrete was originally coated with an epoxy coating which was showing signs of cracking and delamination. As these fountains were located in the central reception area of a very busy hotel any remedial work had to be carried out quickly with minimal disruption to guests. The need was for a lining system that would cure quickly allowing quick return to service, flexible UV and chemical resistant and could function under full immersion.

Radisson Hotel: Nashville Airport

Existing roofing system was an 18 year old 24000 ft2 PVC fully adhered membrane roof. The PVC was showing signs of weathering and needed some patching to stop leaks. There were also flat areas on the roof where ponded water would collect. Under new ownership and as part of the overall refurbishment of the hotel, it was decided to recoat the roof to extend the working life. The problem was finding a roofing system that would adhere to the PVC and that would also handle ponded water.

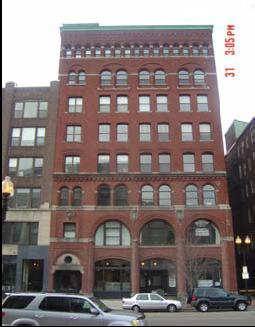

717 Atlantic Avenue Elevator Pit, Boston

The elevator pit needed to be deepened to satisfy building codes. The elevator shaft was also prone to frequent flooding due to the high water table. Geotechnical investigation identified Perchloroethlene (Perc) in the ground. Perc is extremely volatile and classified by the EPA as a Class1 carcinogen. Perc is a strong solvent and very aggressive to most waterproofing materials. The problem was finding a waterproofing system that would resist Perc. Under the direction of Environmental Consultant GZA, contaminated water was collected and used to test Rawmat HDB membrane to prove that the product would be resistant to the Perc contaminated into system.